Milk Procurement and Processing

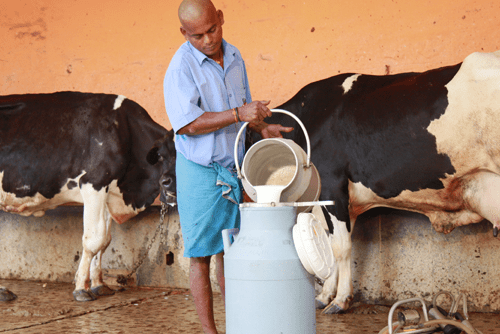

It is our firm belief that unless Raw Material i.e. milk, is fresh and hygienically procured, the quality norms can never be achieved even after having processed through the best available machinery and equipment. This has made milk procurement an important function in the modern dairy industry and our dairy is no exception. To achieve this, the testing of Raw Milk both at village level collection centres and milk chilling centres and at the level of the central dairy plant is done according to the strictly laid-down quality norms of the company. At the same time, we ensure that the milk producers receive better remunerations for their produce (milk) throughout the year.

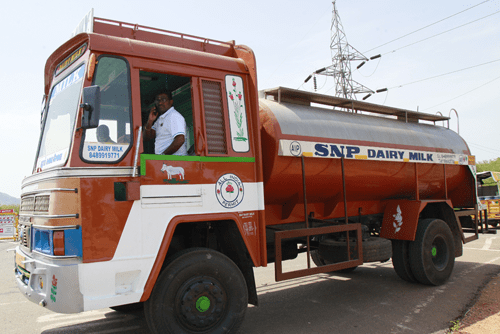

We procure our milk directly from the farmers on a daily basis to maintain hygiene and cleanliness. Our dairy has more than 5,000 registered farmers spread across 100 village-level collection centres owned by the company. The collected milk is immediately transported to our own milk chilling centre. The chilled milk is later transported in insulated tankers to our dairy plant for further Processing.

Our state of the art modern daily plant is equipped with the latest technology and machinery. The present handling capacity of the plant is equivalent to one lakh litres of liquid milk. Chilling, pasteurization, homogenization, product manufacturing, packing etc. are different stages of processing that is carried out under a controlled environment with quality as a priority.

Milk & Milk Products Packaging and Logistics

We have installed plant and machinery to process and pack up to 1,00,000 liters of pasteurized milk in pouches every day. Besides marketing the milk, the plant has all the necessary machinery for manufacturing & packing Butter, Ghee, Paneer, Flavoured Milk, etc within the remaining handling capacity of milk. The latest processing equipment of high-tech automation with online recording facilities are contributing to the desired quality and good manufacturing practices

Milk and milk products are packed in a conducive and controlled environment to maintain product quality. Higher standard packing materials are used for primary and secondary packaging. All the packing materials are food-grade materials that meet the industry standard.

After filling, the packs are stamped with batch code, manufacturing, and expiry details, and mark running number for ghee, etc. All the packed products are stored either in cold storage or ambient storage depending upon the temperature required for different products.

To maintain freshness and fast delivery, our logistics division is strengthened with the necessary infrastructure, including company-owned cold room facilities in main cities. Milk insulated trucks to different storage points and market places located in south Indian cities. A well-Established distribution and retail network ensures smooth and fast delivery of our products at consumer convenience.

Quality Policy and Standards

Over the years, SNP Dairy has invested heavily in technology & testing, keeping its infrastructure up to date for maintaining the best quality of its products. We have state-of-the-art machinery automating the processing of milk with computerized reporting, eliminating the need for manual intervention. We’ve always been the first one in the market to adapt to the ever-changing technology.

The milk producers are educated by our well experienced field officers about the rearing & up-keep of milch-animals and also maintaining the hygienic conditions during milk production. After milk is collected at the village level collection centres and milk chilling centres, the sum is quickly transported to the central dairy plant so that the freshness and purity of milk remains intact-thus eliminating the role of middlemen and avoiding adulteration or deterioration of quality in any manner.

We follow stringent quality checks for physical, chemical, microbiological and residue monitoring levels at different stages of production to ensure superior standards of milk and milk products. A highly sophisticated quality control lab has been established in the unit. The FSSAI Centralized certified company has been obtained since the inception of the plant. This unit is certified with ISO 22000:2005 FSMS for Food Safety Management System. The Dairy plant is approved by Halal Indian Certified Company, APEDA Registered Company and Agmark Certified for GHEE.

Our Certificates